Latest News

- 26 July 2024 - opening rubber prices: TOCOM RSS3 DOWN - BKK UP / KL LATEX UP - BKK DOWN - DOMESTIC SHEET UP - LATEX DOWN

(Last Updated: 26 Jul 2024) - RUBBER PRICES IN IMPORTANT MARKETS

(Last Updated: 26 Jul 2024) - CURRENCY & OIL PRICE

(Last Updated: 26 Jul 2024)- WEATHER

(Last Updated: 26 Jul 2024)- FIELD LATEX PRICE : MOVING AVERAGE PRICE

(Last Updated: 26 Jul 2024)- Weather satellite link

(Last Updated: 25 Dec 2023)- INDIAN STANDARD - Ammonia Preserved Concentrated Natural Rubber Latex ( Second Revision ) ICS 83.040.70

(Last Updated: 22 Aug 2023)- ISO TC45 MEETING BERLIN 26TH OCTOBER - 1 NOVEMBER 2019 -I

(Last Updated: 25 Jul 2022)- Kerala's Rubber Plantations - An Overview

(Last Updated: 17 Nov 2020)Products

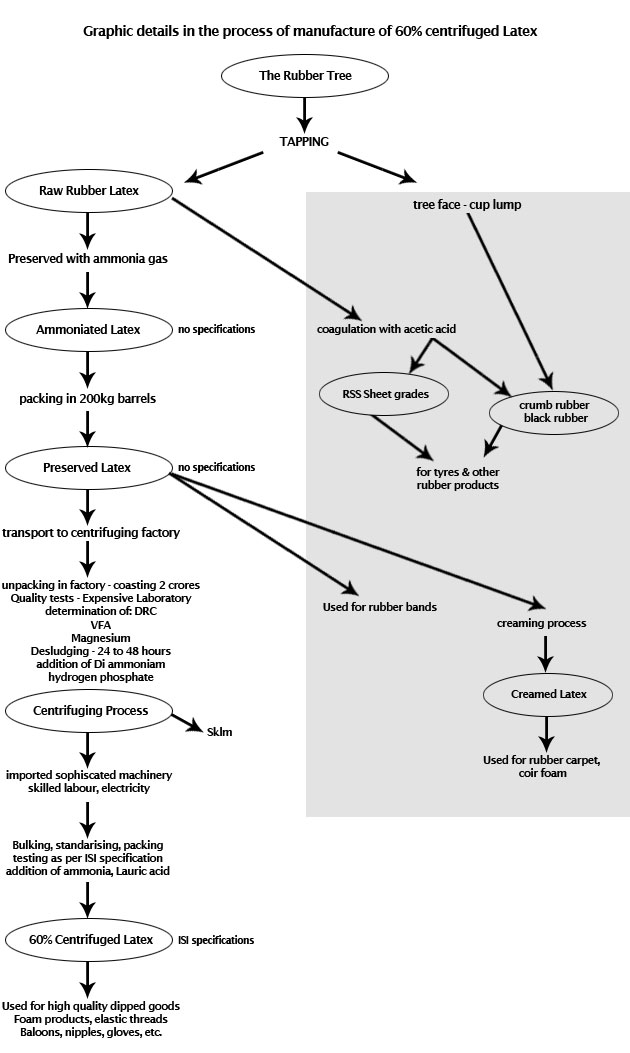

Centrifuged Latex of 60% of Dry Rubber Content (CENEX)

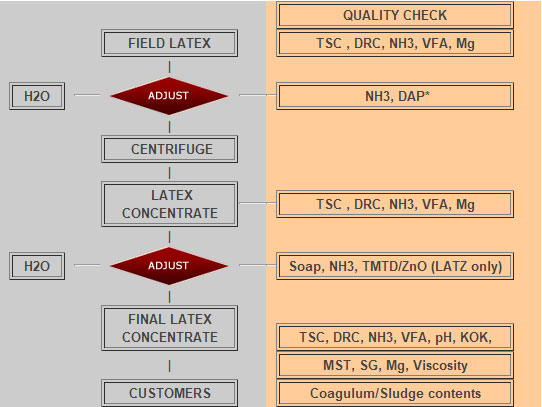

Processing of natural rubber latex into high quality latex concentrate of 60% dry rubber content is done through centrifugation. Centrifuging involves the separation of preserved field latex into two fractions, one containing the concentrated latex of more than 60% dry rubber and the other containing 4-6% dry rubber. Centrifuged latex is today available commercially in two different verities with high ammonia (min.0.7% of ammonia) and low ammonia (max. 0.3% of ammonia). The former is preserved solely with ammonia and later contains one or more preservatives besides ammonia. LA latex has several advantages which include better quality, lower cost of production by way of savings in preservatives, acid and low cost of effluent treatment.

Grades and Applications

- High Ammonia (HA) - Foam products, dipped goods, adhesives, elastic thread, household and industrial gloves, balloons, rubber bands and finger caps.

- Low Ammonia (LATZ) - Preferred for all applications when de ammonia is necessary for product manufacture. Requirement for centrifuged natural rubber latex is given in the table.

Characteristic Requirement Type-HA Type-LA Dry rubber content, percent by mass, Min 60.0 60.0 Non-rubber solids percent by mass, Max 2.0 2.0 Coagulum content, percent by mass, Max 0.05 0.05 Sludge content, percent by mass, Max 0.10 0.10 Alkalinity as ammonia, percent by mass of latex 0.6 Min 0.3 Max KOH number, Max 1.0 1.0 Mechanical stability, Min 475 475 Volatile fatty acid number, Max 0.15 0.15 Copper content, ppm of total solids, Max 8 8 Manganese content, ppm of total solids, Max 8 8

HA – High Ammonia, LA – Low Ammonia - Double Centrifuged and Radiation Vulcanized Natural Rubber Latex (RVNR Latex) - High technology dipped products such as condoms, examination gloves, surgical gloves, catheters etc. These products require a more pure form of concentrated latex. Usually this is achieved by a second stage of centrifuging. Ordinary centrifuged latex is diluted to about 30% drc and then centrifuged to 60% drc. Specifications for double centrifuged latex are prescribed in IS 11001:1984, which is given below.

All the latex processing companies in India take care to ensure supply of high quality contamination free product. It is packed in good quality barrels of 200 + or – 5 kg and or in high quality flexy bags, as per demand.

Creamed Latex

The processing of latex into creamed concentrates involves the mixing of a creaming agent such as ammonium alginate or cooked tamarind seed powder with properly preserved field latex and allowing the latex to separate into two layers, an upper layer of concentrated latex and lower layer of serum containing very little rubber. The lower layer is removed, leaving the latex concentrate of 50%-55% drc which is tested, packed and marketed.

Latex Centrifuge

Latex Concentrate Manufacturing Diagram

Latex Concentrate is used in the production of the following end products:

Medical Gloves - Sterile & Non-sterile Industrial Gloves Household Gloves Toys Condoms and other forms of rubber prophylactics Non-pneumatic Wheels Clothing Rubber Bands Mattresses Rubber Thread Toys Gaskets Door Mats Car Mats Castors Balloons Shoe Soles

Packed 60% Latex In Barrels

- WEATHER